At Teq4 our mantra is Designing for Certainty. Extensive experience has taught us the benefits of perfect preparation, for measuring twice and cutting once. Our approach ensures we minimise our time on site and deliver the absolute best solutions.

Even the best planning can fall short when inaccurate or incomplete site-specific data is shared. This becomes particularly challenging when multiple disciplines are relying on each other to deliver as planned. It is all very well to precision manufacture, it is also crucial to precision build.

Imagine positioning a precision structure on a drawing which itself is already incomplete by a few millimetres. This can result in the actual location being several centimetres or even meters out when setting out on site which will inevitably impact other on-site works and create delays and added time on site. As is always the case, time is not on our side. How to avoid such time consuming and costly errors? Unified: Build from Teq4.

Process

Unified: Build is a process. It enables Measuring; Surveying; Setting Out and Verification. It’s a set of controlled, versioned documentation and specifications that define and inform the entire process of creation from design, through manufacture, to install, testing, commissioning and maintenance.

This comprises not only tight technically specified documentation for use in a family of Unified: Build components (such as : Dot & : View), but also a framework, rigorous implementation structure and tools for controlling and publishing variations and revisions (which there will be) to ensure that all team members, in all locations, are working from the correct drawings and documentation, everywhere, all the time.

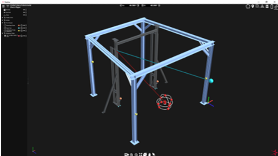

Based upon Leica’s 3D Disto and with the capability to expand to uplift large-scale projects and works, Unified: Dot defines a system and interface to facilitate high-confidence measuring, surveying, setting out and verification on all key positional factors throughout the build and installation phases of production.

Unified: Dot

Unified: Dot – CAD scan view

With the use of : Dot from the initial surveying/modelling stage of a project – and definition of Unified: Zero (defined reference point for the project) – see CAD scan view – it can reduce risk, ensure compatibility and clash-free installation and remove concerns about site plan accuracy. : Dot allows for high-quality verification at all stages and creates accurate as-built models quickly and efficiently.

: Dot’s relationship to Process gives surety that all stages of implementation follow the latest designs, drawings and models at all times, without fail.

Take a look at the video below to see how Unified: Build helped our little friends land their spacecraft.